'Hands-on Help for SMEs' and Smart Technical People'

Lean Manufacturing PDCA Deming

Plan, Do, Check, Act (PDCA)

The

Deming Cycle

Lean Manufacturing Tools and Techniques

Plan, Do, Check, Act (PDCA) is a continual improvement methodology championed by one of the founding fathers of quality management, Dr. W. Edwards Deming. PDCA is an approach that emphasizes, once improvements have been identified and implemented, we should then seek out additional ways of making further improvements and that this process should be continuous.

Plan

The first stage involves planning in the conventional sense, with perhaps more detail and effort than is typical. The idea here is that thorough planning precedes smoother and less troublesome doing. The planning stage also involves communicating your intentions to others involved, explaining and possibly training. Other considerations at the planning stage include understanding the problem down to its root cause, setting clear objectives for everyone, as well as fully understanding what the customer wants (who may be internal).

Do

This stage is all about carrying out the action or improvement – your goal identified at the planning stage. As ‘do’ is all about implementation, it can be the stage people gravitate to first, often without sufficient planning, particularly if there is pressure to see quick results - so be careful. On the other hand plenty of planning should make the ‘doing’ relatively

Check

This is the stage where individuals and the organizations can learn the most. As such, this is how they actually improve. Plan in time to review and ask questions. Examples include:

- Did the implemented improvements actually have the desired benefits?

- Were problems and issues actually resolved?

- How are employees finding the arrangement?

- Are your objectives being met?

- If not why not? – keep asking ‘why?’ until you find the root cause.

- Is there anything you would do differently next time?

This stage is all about the classic ‘lessons learned’. Don’t let poor planning and consequent time pressures let you or your team miss this precious opportunity to learn.

Act

Act is all about standardizing the new best way of doing things. Even though it is the new standard and captures how things should now be done, it should be thought of as something that will be replaced by the latest ‘standard’ way of operating, the next time you move though the improvement cycle. Documenting and communicating the standard is an important part of this stage. Before moving on to the next improvement cycle, consideration should be given to trying to prevent recurrence of any issues and importantly, to holding any gains that have been made. Finally, improvements should be celebrated with praise and recognition.

Lean Manufacturing PDCA Deming

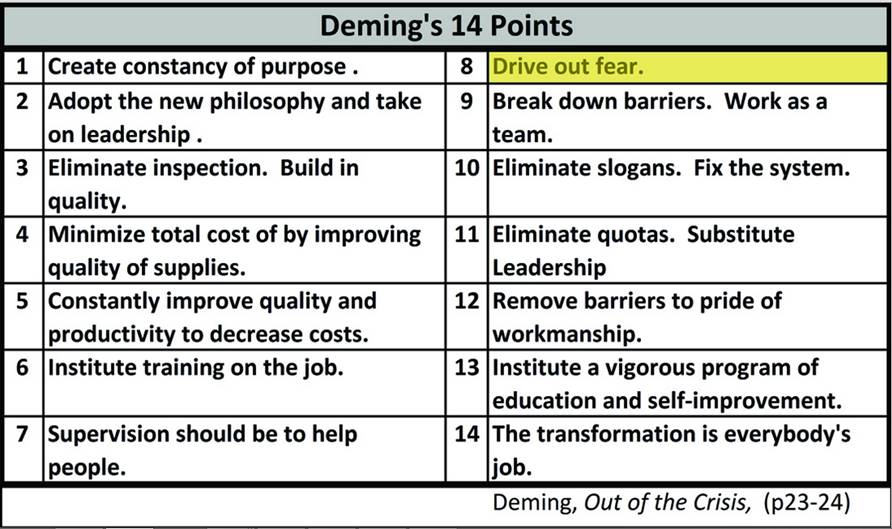

The remarkable Dr. W. Edwards Deming and his huge impact on Quality Management

PDCA - The Basics: Clear and Simple Explanation (courtesy of VelactionVideos)

Kaizen is a

powerful, effective, yet straightforward and therefore inclusive Lean

Manufacturing tool. A major contributor to Kaizen is featured below:

The Kaizen Institute - Website: www.kaizen.com

Next...5 Whys Problem Solving

Back to Lean Manufacturing Essentials

Lean Tools - Best Thing Since Sliced Bread?... Or Hugely Overated? What do You Think?...

What is your experience when applying Lean Manufacturing Tools in the workplace? Which ones have you tried and had success with?

Alternatively, which just didn't work, especially in the long term? - Share your story... and get a FREE copy of our report 'Helping You and Your Manufacturing Business Thrive'...

PS: Feel free to name-drop your firm! There's nothing wrong with a bit of free publicity!

What Other Visitors Have Said

Click below to see contributions from other visitors to this page...

Case study of the PDCA cycle

One of the best case study of the PDCA cycle I found here:

http://smartmanagement.info/world-class-manufacturing/pdca-industrial-case-study/