'Hands-on Help for SMEs' and Smart Technical People'

Industry Best Practice Examples

Advanced Manufacturing Security Industry

Advanced Manufacturing for Defence and Security Applications: Manufacturing Technology Centre

Advanced Manufacturing Security Industry:

I had the pleasure of visiting the Manufacturing Technology Centre recently; one of the 7 UK High Value Manufacturing Catapult centres. The Advanced Manufacturing Security Industry event featured 9 outstanding presentations from universities working closely with industry and defence engineers. The Defence Scientific and Technology Laboratory (Dstl) and the UK Ministry of Defence played hosts. The presentations provided an insight into some of the latest advanced manufacturing innovations for defence and security applications. Topics covered included new alloys and materials for additive manufacturing (including multiple materials), novel structures, composites and electronics.

With a captive advanced manufacturing security industry captive audience, Dstl took the opportunity to ask those present to submit suggestions describing how to scope a call they intend to put out. The call will request industry and academia demonstrate the enhanced functionality available for equipment produced by techniques such as additive manufacturing. Dstl will fund promising research suggestions.

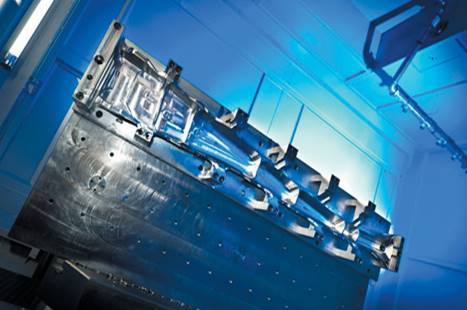

A tour of the Manufacturing Technology Centre provided a practical demonstration of some of the cutting edge research taking place there. Activities include manufacturing process optimisation, cutting edge metallic additive manufacturing research, automation of a range of very complicated processes which currently rely on highly skilled operatives, as well as intelligent equipment capable of combining a number of manufacturing processes into a single machine. Common themes on the tour included, very high levels of precision and accuracy, a spotlessly clean working environment and typically out-sized R&D concept demonstrator equipment. A link to the Manufacturing Technology Centre can be found here.

The networking at the event was exceptional. Everybody enthusiastically swapped experiences and contact details. Attendees from industry, academia and government discussed the presentations, together with the latest research and applications at their places of work.

Additionally, there was representation from the Knowledge Transfer Network, focusing on materials, as well as aerospace, aviation and defence. Click here for more about them. So opportunities for future events and engagement look good. As the event took place inside, diggers where active outside, extending the Manufacturing Technology Centre to cope with increased demand from industry, which can access these great facilities and expertise. All-in-all, an inspirational industrial visit!

Mark Lynch,

Director, Advice Manufacturing

Advanced Manufacturing Security Industry

The Manufacturing Technology Centre - State-of-the-art Applied Research

MTC - Real World Problem Solving Solutions

Advanced Manufacturing Security Industry:

What Cutting Edge Manufacturing Looks Like in the Defence Industry....

Keeping with the theme of advanced engineering in the defence and security industry, click on any of the images below to see how BAE Systems new titanium parts facility will help keep F-35 Lightening II combat aircraft production on track. The report is supplied courtesy of The Engineer. Hot Topics include....

- Computer Integrated Manufacturing (CIM) and Just in Time (JIT)

- Flexible Manufacturing System (FMS)

- Fully automated Tool Management System (TMS)

- Heavy use of robotics and automation

- Relentless focus on efficient manufacturing and minimised machining cycle times

F-35 PRODUCTION RAMP-UP

BAE Samlesbury site prepares for STOVL combat jet manufacture

Courtesy of Professional Engineering, IMECHE. More...