'Hands-on Help for SMEs' and Smart Technical People'

3D Printing Jigs

3D Printed Jigs, Fixtures, Gauges and Manufacturing Tools

How production-based SMEs can justify and get great use from 3D Printers

Simplify and shorten your manufacturing & assembly set-up

3D Printing Jigs: Assisting Small Manufacturers & Justifying ROI to Senior Managers

Most of the interest in 3D Printing has focused around prototyping and the manufacture of components during product development. However for small manufacturing businesses their true value may be better represented with the less obvious production of jigs, fixtures and other manufacturing tooling.

Importantly in terms of justifying the cost of a printer, if you can show the (costed) time reduction 3D printed jigs and fixtures can deliver, you are far more likely to convince more hard headed senior managers.

Most small manufacturers strive for more efficient production processes and operations. In practice this means quicker machine set-ups, less variation during assembly and fitting, secure part holding and a smoother production routine. Jigs, fittings, gauges and other tooling give you this. However, traditionally these have been precision machined in metal, with the associated costs, time, weight and storage. Consequently many small manufacturers do without them - to the detriment of controlling their processes. But the question to ask is will plastic jigs perform the same function? Is steel critical to the application?

Well this is where 3D printing comes in. Jigs and fixtures can be produced quickly at very low cost. They can help streamline and improve production, fitting and assembly operations. Ultimately they reduce time, costs, defects and increase your bottom line. Here's what you can do to benefit:

- Production engineers, CAD designers and technicians should team-up and review production processes and inspection/quality labs together. They should brainstorm potential opportunities for 3D printed jigs, fixtures and gauges.

- Crucially, involve the guys and girls who routinely undertake tasks and use the equipment. They are the ones with the good ideas, based on daily operation.

- Review some of the videos below to see what others' have done to benefit. Think about how you could adopt, tailor and apply them in your manufacturing business.

- Consider 3D printed jig design as part of a broader 5S, waste reduction or production improvement suggestions scheme.

Opportunities for 3D Printed Jigs

Going back to the point earlier about justifying the investment in a 3D printer to senior managers - start thinking about how you can begin putting the business case together in your SME. Focus on specific areas 3D printed jigs can make a tangible difference for you. When and where have you had set-up problems? What operations are known to be troublesome in terms of repeatability, long set-up times and potential defects? What do employees complain about? Is there the potential for the use of fixtures to help? What time could be saved? What is the cost of this time, based on employee hourly rates?

Think about the potential types of jigs, fixture, gauges and and tooling you could use in your operations. Potential uses include holding, guiding, aligning, locating and clamping. Is there an opportunity to develop an item or device to give you more consistent quality and better safety? How about simple 'go no-go' gauges for rapidly checking the fit and quality of components?

If you already possess the CAD information for your manufactured components, jigs and fixtures can be rapidly designed by taking the CAD data from the inverse or opposite of your item, followed by 3D printing. Don't forget to add draft angles, radii and chamfers for easy fitting.

3D printed jigs and fixtures are low cost and can be reproduced if worn or damaged. Some organisations simply print them when they need them, instead of all the worries and costs of storage, asset tagging/tracing and inventory management. If you finish with them, lob them in the recycle bin.

Review the examples below to see how manufacturing businesses are using 3D printed jigs to make a real difference to their production processes. Shouldn't you be too?

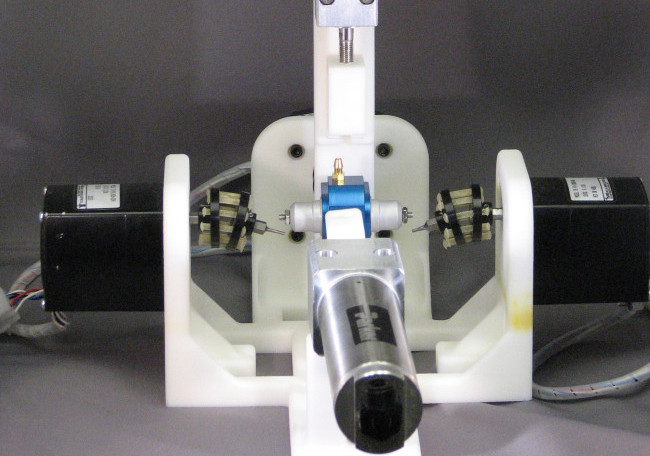

Jigs and Fixtures with FDM 3D Printing (Courtesy of Stratasys)

An informative short video explaining how FDM 3D printing gives you the option of quickly producing jigs and fixtures to assist a variety of assembly and production operations. A range of practical examples are shown with emphasis on time and cost savings. There are plenty of good ideas, many of them ripe for adaptation. It's worth considering potential applications in your production, testing or quality operations.

Additive Manufacturing 3D Jigs and Fixtures (Courtesy of Stratasys & Rutland Plastics)

A short case study illustrating how a manufacturing business have replaced most of their aluminium tooling and fixtures with 3D printed equivalents. Employees describe how the organisation uses 'go no-go' gauges and other fixtures in quality control and other parts of the business, many of which are 3D printed.

Rapid Build of Jigs and Fixtures using 3D Printing (Courtesy of Object)

A description of how jigs and fixtures can be produced quickly and conveniently to hold and mount components during the development process. This compares favourably with typically weeks for metal jigs. Assembly alignment and fitting can be assisted, as can basic operations like templates for accurately applying labels.

3D Printed Injection Moulds (Courtesy of Diversified Plastics, Inc & Stratasys)

A custom injection mould business who have benefited from 3D printed mould tools. They serve a broad range of industry sectors and many of their customers approach them to explore and produce prototype tooling. 3D printing has enabled them to respond in days rather than weeks and therefore help customers get products to market quicker.

Brass and Steel Fixtures Replicated by 3D Printing and then Surface Finished (Courtesy of Stratasys and Armac Martin)

A significant benefit of 3D printing is the speed at which a business can now respond to customer enquiries. Prototypes can be modelled, printed and surface finished very quickly and at low cost. Clients get to see, hold and compare parts before making quicker decisions.

3D Printed Jigs and Fixtures (Courtesy of Stratasys)

Short video describing how manufacturing relies on jigs and fixtures to maintain high levels of quality and manufacturing efficiency. When these are 3D Printed you can save time and money. Also complex geometry can be easily accommodated.

Jigs and Fixtures - A Basic Look: Background definition and refresher.

Understand how different types of jigs and fixtures may help make your production, fitting and assembly processes more efficient. See how routine problems faced in manufacturing operations may present opportunities for you and your colleagues to use jigs and fixtures - with 3D printing being the potential manufacturing method of choice.

Custom Manufactured Tools via 3D Printing (Courtesy of Stratasys)

Even though manufacturing tools are widespread, many manufacturers don't use these tools to their fullest potential. Making them takes time, labour and money. To stretch limited resources there is an option: additive manufacturing. It is simple and automated; it is fast and inexpensive. This allows you to deploy more jigs and fixtures while gaining you the ability to optimize their performance. More

Top 5 Reasons to Print Manufactured Tools (Courtesy of RedEye & Stratasys)

Jigs, fixtures, grippers, gauges and guides—oh my! Walk onto a production floor in any industry and you’re bound to find a wide array of manufacturing tools aiding repeatability, quality and time efficiencies. Even though manufacturing tools are necessary to get the job done right, some manufacturers aren’t realizing their full potential. More

The use of Additive Manufacturing to produce tooling is especially advantageous at low production volumes, as it can eliminate some of the expensive up-front costs caused by design changes.

Many industries have already embraced the use of Additive Manufacturing for tooling, including automotive, aerospace and defense, industrial products, consumer products, and even health care.

Fabricating tooling with Additive Manufacturing offers a number of potential advantages. More...

Next... 3D Printing Future Industry Trends

Back to 3D Printing Additive Manufacturing or 3D CAD Essentials

3D Printing / Additive Manufacturing... Genuine Transformative Technology or Over-hyped by the media? Have your say...

There's been a lot said about 3D Printing / Additive manufacturing. But for manufacturing industry what do you think its true potential is? And is it starting to fulfil that potential?

Some manufacturers have had tangible results. But what's your experience? We’re interested so please let us know!

- Share your story... and get a FREE copy of our report 'Helping You and Your Manufacturing Business Thrive'...

PS: Feel free to name-drop your firm! There's nothing wrong with a bit of free publicity!