'Hands-on Help for SMEs' and Smart Technical People'

Robotics in Manufacturing

Robotic Material Handling

Boost Production, Standardise Quality & Free-up your Workforce for Higher Level Tasks

Plus a range of SME robotics application and case study short videos

Robotic Material Handling Intro

Material handling robots transfer, select and move products or parts from one location to another or sometimes between machines. Employees can be freed up from boring repetitive tasks to undertake more valuable useful activities for you.

Robots on the other hand will quickly and continuously perform manual handling tasks to a guaranteed standard. For heavy, hazardous or awkward work robotic manual handling removes human safety considerations.

Is Robotic Material Handling for You?

You already have some degree of testing and manufacturing automation in your production. And you've heard a lot of noise about the latest breakthroughs in robotics. So what's the right move for your company now?

Whether you're in Pharma, Biotech, Chem, Energy, Shipping, Foods, general engineering or alternatively the automotive or aerospace supply chains, using robotic material handling immediately increases your production, standardises your quality, produces predictability, and frees up your work force for higher level tasks.

The challenge is not in realizing that robotics works, it's in figuring out what to implement and when. How long before you get an ROI from an investment in automating your line? What technologies are the most customisable? When should you upgrade? What solutions are your competitors looking at?

Robotic Material Handling Video

Let's Discuss Freeing Up Your Manufacturing

A lot changes when you take the "man" out of manufacturing

We have an award winning blog on Robotics and Robotic Material Handling. We design robotic manufacturing processes for clients globally. And you? Let's chat!

Bobby, VP Robotics @RoboticsMFG material-robotics.com

Courtesy of RobotWorx, experts who integrate and sell manual handing robots. A few applications include: Two Fanuc M-710iC/50 robots moving and stacking rubber rings, a Fanuc M-1iA spider robot with a suction gripper, and a Motoman HP50 robot with a vision system that lifts and stacks ingets from a conveyor.

Automation IG custom robotic material handling cell. Custom designed cell, conveyer, pallet handling hardware, and EOA tooling resulted in increased efficiency of packaging operation and elimination of packaging backlogs.

Kaufman Engineered using FANUC Robots in an integrated system to undertake a range of automated tasks. These include palletizing, labelling, sorting (using a vision system), collating and stacking.

Courtesy of Mitsubishi. Turning to robots for automated material removal can improve conditions for your employees. You don't have to worry about robots developing repetitive stress injuries. Robots can also improve the quality of the deburring operation by performing the task with a high degree of consistency.

Kawasaki RS080N Robot loads parts in a Brother CNC machine.

The RFA-Vision systems is connected to 2 camera's: camera 1 is mounted above the infeed conveyor for small parts, camera 2 is mounted above the pallet for large work pieces. The robot is equipped with a gripper changing system, the robot can use a 2 finger parallel gripper or a gripper with 3 fingers for round work pieces.

This robotic machine tending demonstration features the FANUC LR Mate 200iC robot. This robot is equipped with iRVision, an FS-15iA Force Sensor, and FANUC's machine tool connection software, which all play an intricate role in completing the job.

FANUC's intelligent Force Sensor provides complete inspection of the machined part by gauging its outer diameter. Precision gauging technology is ideal for job shops with small-batch product runs.

The robot unloads a machined part and loads a raw part into the lathe. It then presents the part to the force sensor. The robot's iPendant displays the results from the gauging. The results shown here display which parts pass or fail, and the diameter for the entire batch of parts as the robot cycles through them.

Advanced Intelligent Systems Inc. By using 1 ABB IRB 1400 and 1 pneumatic linear feeder it is possible to support loading and unloading of aluminium parts for 2 CNC machines. Increasing throughput and efficiency were the major goals of this project.

Robo Jobs Solutions: Small Parts Robotics Assembly

Universal Robots has reinvented industrial robotics with lightweight, flexible robot arms. Tasks previously thought impossible to automate due to cost and complexity, are now achievable with the user-friendly robots.

The Danish-designed robot arms work separately or as dual arms demonstrated here with the UR5. In more than 45 countries, from the small machine shop to the large auto assembly line, Universal Robots optimize production, relieve employees from strenuous or monotonous tasks, and ensure quality control.

ABB Robotics: Every year the International Federation of Robotics (IFR) issues statistics on the top applications for industrial robots. This movie features examples from the top 10 - including Arc Welding, Spot Welding, Materials Handling, Machine Tending, Picking Packing Palletizing, Painting & Assembly

Kindly provided by RobotWorx: Here is a basic breakdown of how a standard 6-axis robot works. The way it rotates, how it is programmed, and even the different types of tooling and grippers are covered in this informative video. RobotWorx is an industrial robot integrator that buys and sells new and used robots and can create customized workcells for manufacturers.

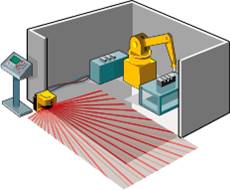

Top Tips for staying safe when working alongside Robots

(Courtesy of FANUC & Industrial Technology)

As the number of robot installations increases, so inevitably does the interaction between people and their robotic colleagues. This means the issue of worker safety is raised to the fore. So what steps should you take to avoid robot-related accidents when humans and robots are sharing the same workspace… more

Using Robots for Bespoke and Low Volume Processes

(Courtesy of ABB Robotics & Industrial Technology)

The benefits of robotic automation for mass production processes are well recognised and understood. Visit any modern automotive plant, for example, and you are likely to see rows of robots engaged in a broad range of activities, each playing their own specific role in production. There are an increasing number of examples of companies that are integrating robotic automation into low volume processes across a range of applications, from production of medical devices through to welding and parts handling... More

Busting the Myths around Robotics for SMEs

(Courtesy of Pacepacker Services & Eureka Magazine)

In many industrial operations they have long been integrated into wider automation and production processes. Why then are so many SME's,still deterred by robot technology and cautious about applying it to their processing and packaging operations? Time to tackle the most persistent myths... More