'Hands-on Help for SMEs' and Smart Technical People'

3D Printing Bureau Services

How 3D Printing Outsourcing Offers a Convenient Professional Service for Engineers and SMEs

Plus 3D Printing Industry and Additive Manufacturing Industry access via a 3D Printing Directory

3D Printing Bureau Services

Are you thinking of seeing what 3D Printing can do for your organisation, but not quite ready to make the financial outlay yet? Alternatively, is the outsourcing route via 3D Printing Bureau Services, more suited to the way you do business?

Well the good news is the 3D Printing industry is well served with a range of businesses that have set themselves up as bureaus. The idea here is design engineers can send 3D CAD data to these firms who then take care of all the printing issues. This has a number of distinct benefits for the customer...

3D Printing Bureau Services: The benefits...

- This is a low cost way of obtaining cutting edge 3D Printed parts, without investing in the hardware. Therefore you do not have to outlay for the upfront cost of the equipment, it’s maintenance or running costs.

- Bureaus offer a range of 3D Printing technologies and materials. As these all have pros and cons, you can select the one that best meets your application.

- You do not have to invest in the skills or find the space to operate the equipment or store the material. Additionally, some technologies like SLS require quite a lot of housekeeping. When outsourcing to a bureau, you don’t need to worry about any of this.

- Many bureaus offer model making and finishing services, as well as 3D Printing. This enables you to obtain extremely impressive and realistic mock-ups and exhibition pieces, which combine the techniques’ exceptional quality finishes and aesthetics – ideal for product launches.

- 3D Print Bureau employees possess a huge amount of experience and knowhow. Some of them act as consultancies offering design support, advice and tips. Importantly they can ensure the CAD files are ready to print, surfaces are watertight with no gaps, and the model is in the best orientation for strength when printed.

- Most Bureaus pride themselves on good customer-service and ease of use. After all they live or die on their reputation and repeat business.

- Outsourcing to bureaus is convenient. The hard pressed design engineer in a small manufacturing business is likely to be juggling a whole range of tasks. Outsourcing enables prototyping to take place concurrently alongside other tasks, thereby shorting development times.

- It is quick! 3D Printing experts can turn around orders often in under a week.

- Bureaus provide an opportunity to ‘try before you buy’ for those manufacturers considering making an investment to bring the capability in-house. Outsourcing gives the business a chance to examine the technology, see how much they use it, explore novel ways of applying it and ultimately make a judgement as to whether they can justify the investment based on likely use.

|

The TCT Supplier Directory A comprehensive list of solution providers in the Additive Manufacturing and 3D Printing arena searchable by location and provision. Click Here |

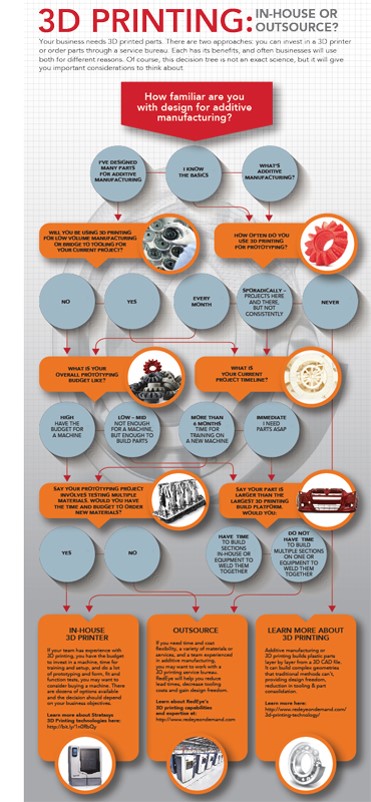

An excellent illustration courtesy of makepartsfast.com

When do you stay in house, and when do you outsource? These tips will help you make the right choice. More information about the key considerations here

3D Printing Bureau Services useful information by 3D Print Headquarters

Why Should I Outsource?

There are a number of reasons that often make companies deem outsourcing to 3D printing companies a better option.

To begin with, despite the fact that the cost of 3D printers has been consistently dropping over the years, you need to understand that buying a 3D printer is still quite an expensive investment for any business. Remember that especially if you want to be providing products of great quality, you’ll have to go for a high end printer. Such printers can cost an organization a considerable amount to purchase only a single printer.

Moreover, for a company to be able to produce a wide range of products, it is normally essential for it to buy several 3D printers. If you compare this to the cost of outsourcing, it is clear that outsourcing is far more affordable. More...

3D Printing Bureau Services useful information by 3D Prototype Projects

What’s the business case for in-house 3D Printing, when compared to outsourcing to 3D Printing Bureau Services?

- Company size: the six-figure price tags attached to industrial 3D Printing technologies may put them out of reach for SMEs (small and medium sized enterprises) – as well as many large organisations for whom it may be more cost effective to outsource.

- Capital investment plus ongoing cost: the total cost of bringing 3D Printing in-house is significantly more than the initial capital investment cost. The annual and ongoing costs of operation and maintenance may run in to further tens of thousands of pounds.

- Requirement for 3D Printing: if your company designs, develops and manufactures products in-house from drawing board to production line, there may be a clear business case for investing in specific 3D Printing technologies in-house. Indeed, machines may be worth investing in both for prototyping or production part manufacturing purposes.

- Scale: scalability of part production must be a major consideration as large scale volume production of parts may require multiple machines.

- Range of prototyping requirements: there are many types of 3D Printing, each capable of producing parts using different materials with different properties, characteristics and finishes. If your business prototyping needs may extend to many types of parts, properties and characteristics, you will most likely require more than one kind of 3D Printing technology in house.

- Training and development resources: operating and maintaining 3D Printing technologies requires extra staff – all of whom need training, development and management.

- Evolving technology: the lifetime of a 3D Printing machine may be limited by the speed with which the whole field is evolving. No business wants to spend £ hundreds of thousands on technology that will become ‘legacy’ within a short period of time.

Conclusion

Pure business logic suggests that most companies other than the largest manufacturers are advised to outsource 3D printing rather than bring it in house.

The business case for an investment of £ hundreds of thousands (perhaps £ millions) is difficult to make if a business is unlikely to produce enough 3D printed parts to justify the initial outlay – let alone the operational costs.

On the other hand, the business case for outsourcing 3D Printing to professional bureaus such as Prototype Projects, with a complete range of machine types, technologies, materials, expertise and volume capability is likely to be far stronger. More...

Next... 3D Printing Materials

Back to 3D Printing Additive Manufacturing or CAD Engineering Essentials